Supply Chain Management

Challenges and Opportunities

Supply chain management presents several challenges for businesses, as it involves multiple factors, from responsible sourcing of raw materials and cost management to minimizing environmental impact and ensuring transparency and fairness throughout operations. Changes in the business landscape, such as stricter environmental regulations, evolving consumer expectations for sustainability, and the complexity of global supply chains, require Central Retail to be highly flexible and adaptive. This ensures smooth business operations without compromising sustainability.

Despite these challenges, supply chain management offers significant opportunities to enhance competitive advantage and increase business value. Integrating Environmental, Social, and Governance (ESG) principles into operations helps reduce long-term costs through efficient resource utilization, mitigate legal and reputational risks, and build trust among suppliers, customers, and investors. Additionally, supporting government sustainability policies, such as adopting alternative energy sources and reducing greenhouse gas emissions, allows Central Retail to play a crucial role in driving the green economy and creating positive social impact.

Central Retail has implemented various strategies for supply chain management. These include establishing a Supplier Code of Conduct and contractual commitments to ensure compliance with ESG principles, encouraging suppliers to adopt environmentally friendly business practices, and utilizing technology to optimize transportation and energy use. Furthermore, Central Retail prioritizes fair labor management and safe working environments to mitigate social risks. These measures not only help reduce potential disruptions but also strengthen stakeholder confidence, contributing to sustainable and long-term business growth.

Management Approach

Central Retail is committed to managing its supply chain efficiently and collaborating with suppliers and stakeholders on sustainability initiatives. This is achieved through the following key strategies:

- Customer Centric: Understanding customer needs to offer curated products that inspire and impress customers

- Quality and Variety of Assessment: Selecting products with the optimal balance of quality and price to maximize customer value creation

- Sustainable Business Practices: Ensuring all product offerings take into account their impact on society and the environment

Central Retail prioritizes conducting business with suppliers who consider environmental and social impacts. Central Retail has implemented efficient energy usage improvements in its supply chain management processes and has been certified for the energy management system standard (ISO 50001), which contributes to efficient energy resource utilization, reduced operational costs, and lower greenhouse gas emissions. Beyond environmental aspects, Central Retail also adheres to labor practices and respects the human rights of its employees and suppliers, such as reasonable working hours, reduction of excessive overtime, and fair wages. Furthermore, Central Retail encourages its suppliers to participate in environmental, social, and governance (ESG) initiatives by sharing best practices and providing training, as well as integrating sustainability practices into their business operations.

Central Retail Sustainable Supply Chain Management System

Central Retail has implemented a sustainable supply chain management system to ensure that the stakeholders, especially Central Retail’s employees and suppliers, are aligning and complying with high sustainability requirements. To oversee the sustainable supply chain management system and practices, Central Retail has established the Supply Chain Sustainability Committee, led by a Board of Directors from the Corporate Governance and Sustainability Committee. The Supply Chain Sustainability Committee also includes the Supply Chain Director at the management level, along with representatives from merchandising and supply chain teams across all business units. To guarantee suppliers’ compliance, Central Retail has included the Supplier Code of Conduct in the standard contract and trade term agreement. Additionally, Central Retail regularly reviews its internal merchandising practices to ensure they remain aligned with updates to the Supplier Code of Conduct and do not conflict with ESG requirements.

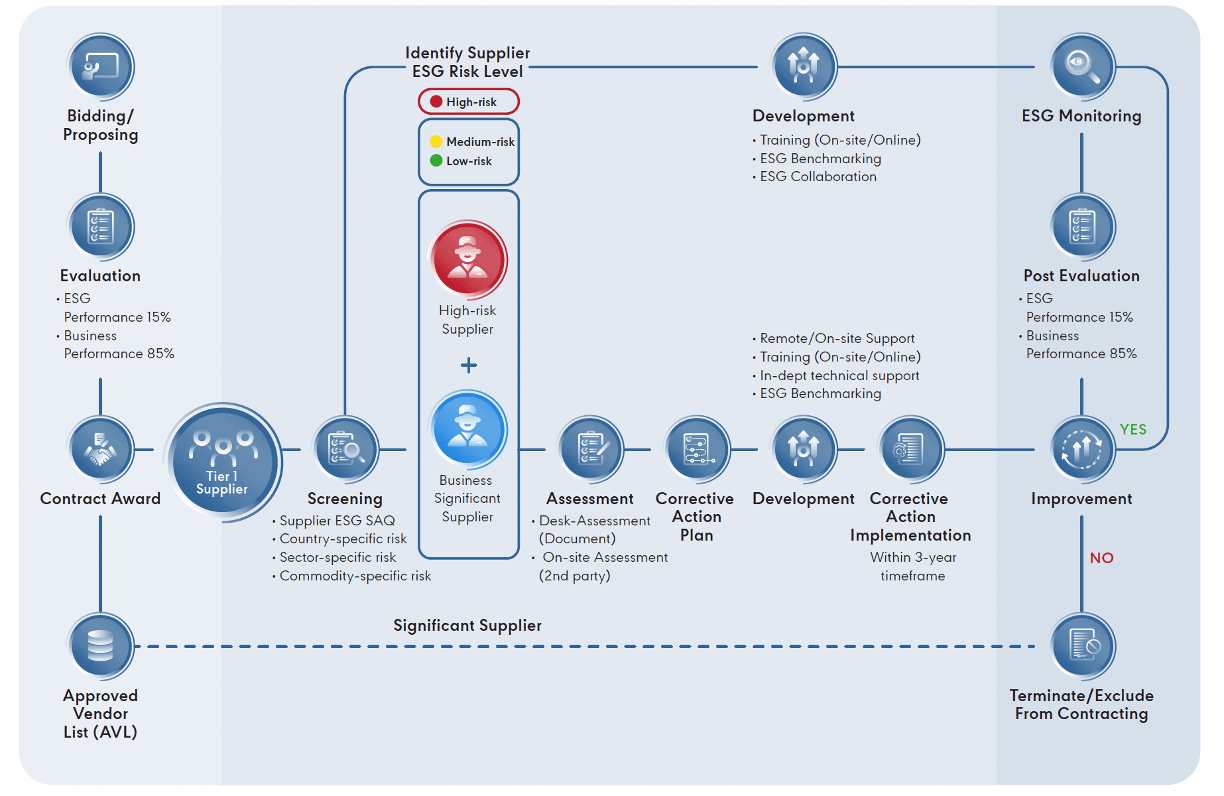

The sustainable supply chain management system follows a comprehensive approach which begins with a supplier screening process that includes a supplier screening matrix and the CRC ESG Watchlist. After significant suppliers are identified, Central Retail undergo a thorough assessment combining both desk and on-site assessment. Based on these assessments, corrective action plans are developed where needed. To develop internal capabilities, Central Retail has implemented an in-depth ESG training program for buyers, merchandisers, and relevant stakeholders. Additionally, Central Retail promotes continuous improvement through supplier development programs and an ESG benchmarking system. This benchmarking allows suppliers to compare their sustainability performance against industry peers, creating healthy competition and motivating them to enhance their ESG practices.

Supplier Screening, Assessment and Development

Central Retail has developed the process to identify and assess sustainability risks throughout its supply chain. The procedure is divided into five steps: 1) Supplier Selection 2) Supplier Screening 3) Supplier Assessment 4) Corrective Action Plan, and 5) Supplier Development . Central Retail has initiated operations with first-tier (Tier-1) suppliers, with plans to extend these practices to cover any remaining suppliers in the future.

1. Supplier Selection

Central Retail has established supplier management measures, beginning with mandatory compliance with our Supplier Code of Conduct - the ESG requirement for all suppliers, both new and existing. Suppliers who fail to meet these minimum ESG requirements within a three-year timeframe may potentially face termination and be excluded from contracting.

The supplier selection process incorporates two key evaluation components:

- ESG Performance (15% weight): Assessed through a mandatory Self-Assessment Questionnaire (SAQ) that evaluates suppliers' existing Environmental, Social, and Governance (ESG) practices and their alignment with the Supplier Code of Conduct. Strong performance in the SAQ contributes positively to a supplier's overall evaluation score which will help them become more preferable, potentially increasing their chances of contract awards.

- Business Performance (85% weight): Evaluated through factory checklist, performance evaluation, and other business criteria.

All suppliers must complete the annual Self-Assessment Questionnaire (SAQ), which helps demonstrate their ESG management practices and processes. Successfully evaluated suppliers are then added to the Approved Vendor List (AVL) and become eligible for contract awards. This comprehensive evaluation process is conducted annually. Following selection, suppliers will undergo more thorough ESG risk evaluations as part of the continuous supplier assessment procedures.

After suppliers are awarded with contract and added to Approved Vendor List (AVL), suppliers must undergo the supplier screening process to identify “significant suppliers”. Central Retail has defined significant suppliers as those with high business relevant to the Company but may also present substantial ESG risks – whether country-specific, sector-specific, or commodity-specific.

2. Supplier Screening

Central Retail has developed Tier 1 and Non-Tier 1 supplier screening processes that utilize two main tools, supplier screening matrix and CRC ESG Watchlist. The supplier screening matrix is an evaluation framework that assesses suppliers through two keys criteria:

-

2.1 Business criteria, considering suppliers who are significant to Central Retail's business in various aspects, as follows:

- Total procurement spend

- component criticality

- Supplier substitutability

-

2.2 Supply Chain ESG risk criteria examine general information, as follow:

- Country-specific risks: Risks of negative ESG impacts related to the political, social, economic, environmental, or regulatory situations of each country.

- Industry-specific risks: Risks of negative ESG impacts related to the specific characteristics of each industry, such as labor conditions, energy consumption, resource utilization, pollution, and pollution potential.

- Commodity-specific risks: Risks of ESG impacts related to the supply chain structure of raw materials or goods, labor conditions, land and resource use, energy consumption, pollution, material toxicity, and pollution potential.

To further strengthen the supplier screening process, Central Retail also analyzes external data sources through social listening techniques. This monitoring helps track potential complaints and compliance issues while verifying adherence to the Supplier Code of Conduct and relevant laws and regulations. The combined outcomes of the business relevance criterias, supply chain ESG risk criterias, and social listening will identify significant suppliers effectively.

3. Supplier Assessment

After the supplier screening, all significant suppliers are required to undergo the supplier desk assessment process, which requires suppliers to submit extensive information and proof to Central Retail for systematic verification. In this process, Central Retail’s supplier code of conduct and SMETA audit methodology are applied as guidelines for the Company to systematically assess suppliers, which focus on 4 pillars: Labor standards, Health and safety, Environment, and Business ethics. Suppliers are required to submit evidence of current and previous ESG-related policies and management systems and metrics to demonstrate good performance, such as reports, records, procedures, and certifications. This systematic supplier desk assessment allows Central Retail to systematically determine and classify the significant suppliers into high, medium, and low risk levels. Significant suppliers with medium and low risks are considered to have passed the supplier risk assessment.

Significant suppliers with high risk will require a more thorough supplier on-site assessment conducted by Central Retail’s employees (supply chain, merchandising, compliance, and audit department) or external parties. With primary data obtained on-site, both Central Retail and the suppliers will be able to gain a more comprehensive understanding of the current situation and identify the fundamental causes of the risk issues. Central Retail will exclude high-risk suppliers from contracting and remove them from the AVL if they cannot resolve their issues and reduce their risk to medium or low levels within a 3-year timeframe.

4. Corrective Action Plan

The primary data and fundamental causes of the risk issues gathered from supplier on-site assessment will be used to develop the corrective action plan for high-risk significant suppliers, assisting with remediation, mitigation, and impact prevention. Such plans contain specific actions, responsibilities, and timeline for addressing the high-risk issues with the purpose of mitigating and resolving any major actual and potential risks.

Following Central Retail and suppliers have agreed to the corrective action plan, the suppliers have to implement and improve pending issues within the 3-year timeframe prior to a follow-up assessment. Once Central Retail has reassessed the suppliers and the results show a decrease from high to medium or low risks, they can be included in the AVL. Suppliers who are unable to complete the corrective action plan or fail to meet the minimum ESG requirements within the specified timeframe will be excluded from contracting.

5. Supplier Development

In addition to monitoring the ESG performance of suppliers, Central Retail also focuses on supplier development by sharing sustainable best practices and offering training programs centered on capacity building. Central Retail provides guidance and support in implementing corrective and improvement actions by offering tailored suggestions to suppliers requiring assistance, which can also be conducted remotely. Progress is closely monitored through regular follow-ups to ensure that corrective actions are effectively implemented. These efforts aim to enable suppliers to align their operations with Central Retail’s sustainability framework and build trust among stakeholders and suppliers across the value chain.

Additionally, Central Retail also conduct supplier ESG benchmarking, categorizes risk levels into high, medium, and low risks, and discloses a list of ESG projects that implemented by suppliers, such as energy saving or water recycling project, environmental policy, anti-corruption, data privacy, and more. This approach provides a comprehensive perspective of suppliers’ ESG initiatives, monitoring performance, fostering collaboration, and encouraging further participation in sustainable practices.

To strengthen supplier relationships, improve sustainability performance, and succeed in long-term goals, Central Retail continues to explore supply chain improvement opportunities, set new sustainability performance goals and targets, and share best practices with suppliers and stakeholders.

Result of Supply Chain Risk Assessment

Supply Chain Management Risks

Supply chain operations face various risks, particularly in supplier management and customer demand responsiveness. These include risks from reliance on single suppliers or products, commodity price volatility, mismatches between products and customer needs in terms of demographics, geography, and tourist groups, as well as product safety risks and demand slowdowns due to war or economic crises. In operational risks, Central Retail considers risks from inventory management that may lead to overstocking or shortages, obsolete products, transportation capacity limitations, and labor shortages in operations.

Furthermore, Central Retail emphasizes the management of sustainability risks, covering: 1) Environmental dimensions: pollution and the overuse of natural resources in both supplier production or sourcing processes and supply chain operations. 2) Governance dimensions: risks from violations of laws related to customs procedures, transportation traffic laws, and risks of fraud in procurement and internal supply chain operations. 3) Social dimensions: risks from supplier violations of human rights, operational safety in warehouses and transportation processes, and the inappropriate use of child labor or pregnant women labor.

ESG Risks from Suppliers

Central Retail has assessed potential risks from suppliers in sustainability issues and found that there are risks that may occur in several dimensions, especially in governance dimensions. Some suppliers lack key policies related to ethical business operations, including policies on business ethics, anti-fraud and anti-corruption, as well as policies on privacy and data security in accordance with the Personal Data Protection Act (PDPA). They also lack transparent and confidential channels for whistleblowing or complaints, which may increase the risk of fraud and affect the reputation of both suppliers and Central Retail in the long term.

At the same time, risks are also found in social dimensions, particularly in occupational health and safety. Some suppliers lack clear policies or measures to promote workplace safety and lack continuous safety training or education, as well as plans or measures to respond to emergencies that may arise from operations. These factors may directly affect work safety, increase the chance of accidents, and may lead to damage to life, property, and the reputation of both suppliers and Central Retail.

Project Highlights

Central Retail Logistics for SME and Sustainability Program

Central Retail conducted the Central Retail Logistics for SME and Sustainability Program for suppliers. The objective of this initiative is to build good relationships and encourage suppliers and small and medium-sized enterprises (SME) to integrate sustainable practices in their work process including procurement, product storage, distribution and transportation, and customer support. This initiative can equip suppliers with technical skills and tools needed to align their practices with Central Retail’s sustainability standards by sharing of basic knowledge and best practices in a total of 267 participants.

Empowering Sustainable Practices

In 2024, Central Retail provided a strategic camp for supply chain management workshop. This program focused on how to integrate environmental, social, and governance (ESG) initiatives into the supply chain operations while demonstrating how sustainable practices enhance cost-effectiveness and operational efficiency. The program offered a workshop on energy and waste management, as well as the principles of the circular economy. Participants gained practical knowledge and skills to transform their supply chain operations. This makes it possible for the employees to understand how to integrate and carry out ESG efforts in the supply chain which there were 101 participants.

Strategic Supply Chain Management (SSCM) Workshop – SET

A panelist in the "Strategic Supply Chain Management Workshop" organized by SET ESG Academy of the Stock Exchange of Thailand. The panel discussion focused on "Supply Chain Sustainability" strategies, bringing representatives from over 60 leading listed companies, including 7 of Central Retail's suppliers. This event served as a platform for exchanging insights and experiences in supply chain management and is also an important opportunity for networking among participating organizations.

ISO 50001 Energy Management

The Supply Chain Non-food Distribution Center focuses on promoting energy management within Central Retail and enhancing awareness about sustainable energy consumption. By organizing the project, it follows the ISO 50001 method, which includes training and development to ensure employees' understanding, energy data tracking, audit and consultation surveys, and evaluation to achieve ISO 50001 certification. All non-food employees in distribution center are engaged in the project, with activities such as internal and external audits, training programs, and recognition through ISO 50001 awards. This project aims to reduce energy consumption by approximately 2% in 2024, with a goal of an additional 2% reduction each following year.